Decalcomania

Noritake employs decalcomania to add decorations and ornamentation to tableware and has developed the technique for a variety of uses. Decalcomania makes it possible to place decorations on materials and curved surfaces that prohibit direct printing, and has recently garnered attention as an alternative to coating. Noritake's decalcomania can be applied to a wide range of materials including ceramic, enamel, glass, resin and metal.

- Decalcomania (Heat-setting type)

- [Examples of Use] ・Resin (carbon, FRP) ・Metal

What is decalcomania?

Decalcomania is a substrate used in printing processes to create a pattern or design. Decalcomania is used at Noritake as a method of transferring decorative designs (including embellishment) to tableware and has been developed for many different applications.

Features of Decalcomania

1.Compatible with various material.

Customers can choose a decalcomania that is suitable for the material involved, including Firing and Heat-setting type. You can also choose the optimal decalcomania material to suit the characteristics of the target material.

2.Decalcomania can be applied in many layers and many colors.

Decalcomania makes multilayered, multi-color patterns and designs possible. Printing can be done directly any number of times on decalcomania, which greatly shortens the amount of time needed to apply decorations.

3.Decalcomania can be applied in areas where direct printing is impossible.

Decalcomania makes it possible to apply patterns and designs to three-dimensional or bumpy surfaces. Wet-slide decalcomanias have particularly good flexibility and surface-conforming characteristics, and beautiful results can be achieved when applied to curved surfaces.

4.For mass-produced printed items, the same pattern or design can be mass-produced.

5.The correct method can be chosen that satisfies the customer's requirements.

Customers can choose from two types: wet-slide (wet transfer) decalcomania that go on using water, or dry transfer that adhere through heat and pressure.

Features of Wet-Slide and Dry Transfer Decalcomanias

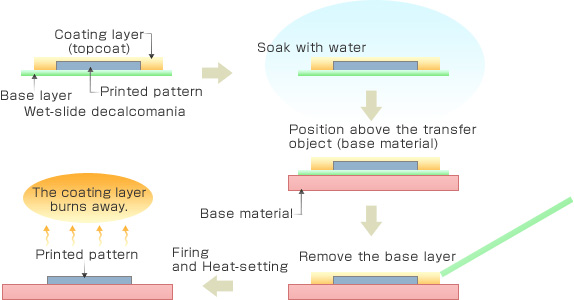

Wet transfer: Application by hand is assumed, so no additional manufacturing investment is required. These decalcomanias also have excellent contour-following characteristics on curved surfaces.

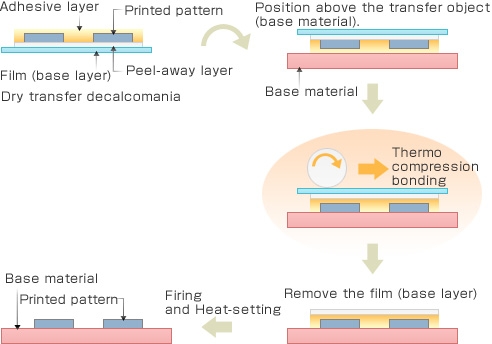

Dry transfer: Automated transfer processes are possible. (Specialized equipment is required.) Direct transfer to the transfer material is also possible.

Decalcomania Sizes

General:480 × 640 (mm), 640 × 960 (mm)

Large: 1,000 × 2,000 (mm) (semi-automatic)

(All paper sizes are available. Actual effective printing surface differs according to the pattern or design, so contact us directly for assistance.)

Decalcomania: Application Process

Wet transfer Decalcomania: Application Process

Dry Transfer Decalcomania: Application Process